Jason – posting this for you so that you can put together all the materials we will need for May 7 welding day

Jason – posting this for you so that you can put together all the materials we will need for May 7 welding day

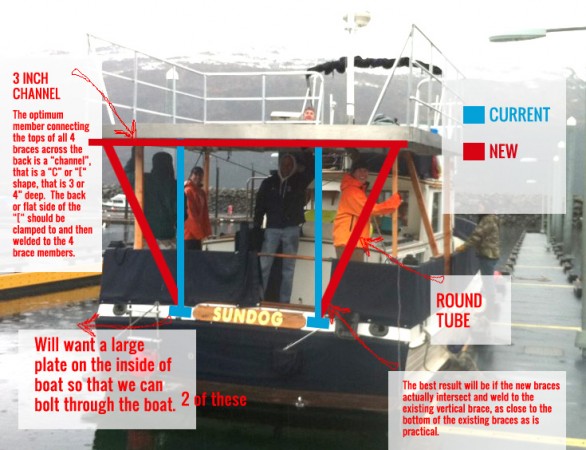

- The best result will be if the new braces actually intersect and weld to the existing vertical brace, as close to the bottom of the existing braces as is practical.

- The optimum member connecting the tops of all 4 braces across the back is a “channel”, that is a “C” or “[“ shape, that is 3 or 4” deep. The back or flat side of the “[“ should be clamped to and then welded to the 4 brace members.

STABILIZING ROOF AFT

Materials List

• Stainless Pipe for support – 2 – about 8′ I would guess

• Stainless channel – 3 or 4 inch to weld to top of supports – 12′ approx he optimum member connecting the tops of all 4 braces across the back is a “channel”, that is a “C” or “[“ shape, that is 3 or 4” deep. The back or flat side of the “[“ should be clamped to and then welded to the 4 brace members.

• The best result will be if the new braces actually intersect and weld to the existing vertical brace, as close to the bottom of the existing braces as is practical. I will have you make a plate for the inside of the boat.

• Need 7″ all thread stainless to bolt through the boat and lock nuts/washers and nylon locking nuts for bolting this all into that aft of the boat Will need 4 total of these – 2 per plate

• Angle aluminum to take out the wobble in the floor – cross pieces welded and floor tacked to them

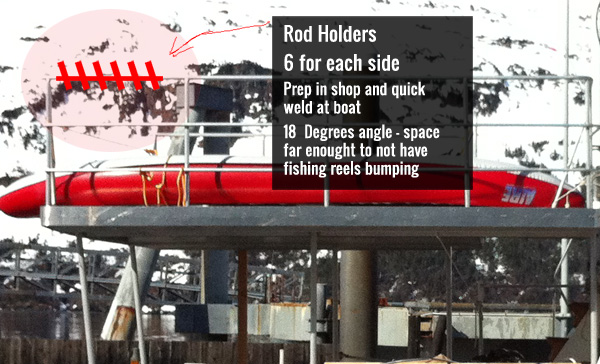

• Rod holders up top – will draw this out – but enough for 6 rods each side – just pipe angled and welded

• Flat bracket for barbecuer – this will just be a plate that we weld up at the upper hand rails that I can mount the barbecue to.

• Possibly hole for stove pipe and a 4″ flu that I can connect to going up.

• Small pipe at middle aft of the back of the roof – this will in escene be for holding a flag pole – but also have some other plans for it.

Rod Holders Image

We Are Social